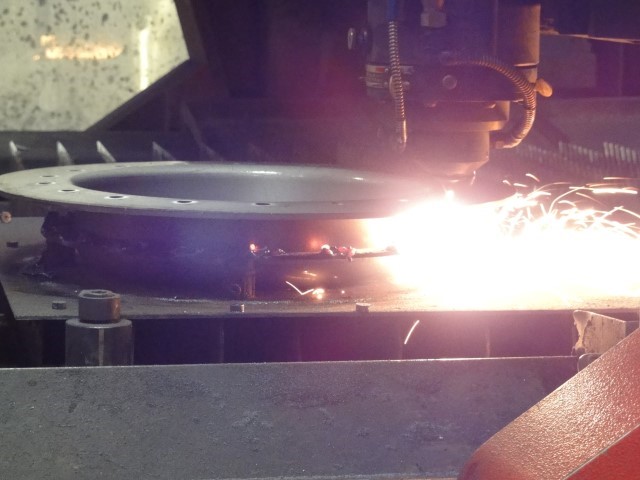

Metal Forming & Fabrication Capabilities

Metal forming and metal fabrication are any process that cuts, shapes, or molds metal materials into a final product. Instead of relying on assembly methods to produce ready-made components, metal fabrication processes create a product from raw or semi-finished materials in a solid state. A range of metal fabrication processes can be used to create custom parts and components for your project specifications.

Contact us for more information on our metal forming capabilities and services, or call us at 651-452-1441, and we will happily assist you with any questions.

Precision Metal Fabrication Capabilities & Services

Tempco Manufacturing specializes in metal forming and sheet metal manufacturing. We are capable of many precision metal manufacturing services, performing metal fabrication on projects ranging from simple standard procedures to custom complex designs.

Metal forming can permanently compress, bend, stretch, or alter the metal material. These fabricated pieces can be utilized for many products. Tempco can provide metal fabrication processes that match your exact design specification needs.

Benefits of Custom Metal Forming

Custom metal forming ensures extreme precision and accuracy for your needs. The advantages of utilizing metal fabrication services and collaborating with Tempco include:

- Consistent replication

- Durability and longevity

- Complete project customization

- Aesthetically pleasing surface finishes

- In-depth communication

- Ability to cut standard and specialty materials

Custom Metal Fabrication Services by Tempco

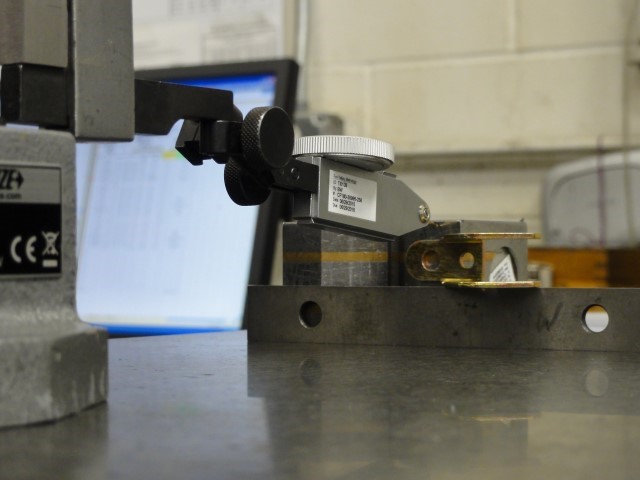

The wide variety of sheet metal manufacturing services Tempco offers allows for customization and project accuracy. We offer extreme precision through the following processes:

Various metal stamping processes include:

- Custom metal stamping

- Turret press

- Precision tooling and fixtures

- Carbon steel stamping

- Aluminum stamping

We also offer engineering and prototype services so that we can determine the best metal forming processes for your project requirements. Our value-added capabilities are sure to fulfill your project demands.

Industries Served

Tempco services many industries requiring sheet metal manufacturing services. Projects for these industries include:

- Aerospace stamping and fabrication

- Medical devices

- Hardware stamping and fabrication

- Metal lighting stamping and fabrication

- Metal manufacturing for firearms

- Automotive stampings and fabrication

- Electronic components

- Construction and industrial equipment

- Food and beverage industry

Contact Tempco Manufacturing for Precision Metal Forming and Sheet Metal Manufacturing Services

Tempco Manufacturing proudly provides high-quality metal forming and sheet metal manufacturing services for various applications. Contact us and let us help you with your custom metal fabrication needs today!

©2024 Tempco Manufacturing Company, Inc.

2475 Hwy. 55, St. Paul, Minnesota 55120

Tel: 651-452-1441 Fax: 651-452-1125

Privacy Policy - Site Map - Site Credits: Ecreativeworks