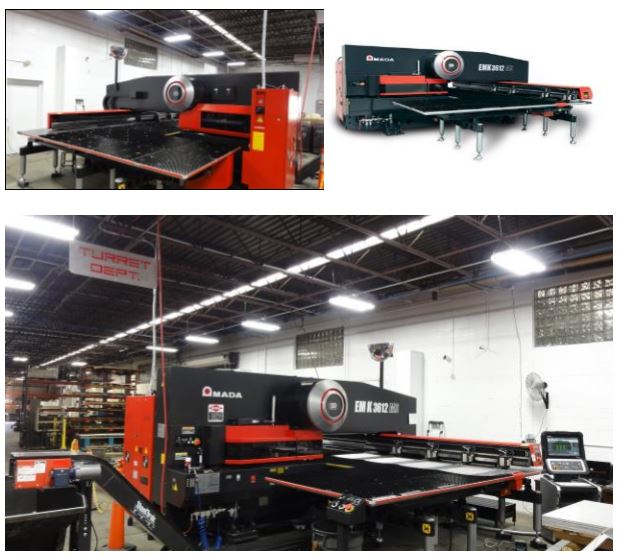

Turret Press Capabilities

As part of our commitment to continuous process and quality improvement, Tempco recently added an Amada EMK M2 Series turret press to our lineup of metal stamping and fabrication equipment. This state-of-the-art Amada system offers the highest real-world hit rates and ram positioning accuracy of any turret press on the market and can process 5’ x 10’ metal sheets without repositioning. What does that mean for you? More precise parts and greater manufacturing efficiency to get your project done better, faster.

As part of our commitment to continuous process and quality improvement, Tempco recently added an Amada EMK M2 Series turret press to our lineup of metal stamping and fabrication equipment. This state-of-the-art Amada system offers the highest real-world hit rates and ram positioning accuracy of any turret press on the market and can process 5’ x 10’ metal sheets without repositioning. What does that mean for you? More precise parts and greater manufacturing efficiency to get your project done better, faster. Better Equipment for Better Parts

Our Amada turret press provides numerous benefits that help us create your metal stampings and fabricated parts with better quality and accuracy. Precision ram motion control—including separate controls for speed, stroke length, hover height, and hold time—reduces tooling wear and punching noise. This benefits both our customers (more parts with fewer tooling changes for faster service) and our production team (quieter is always better!).

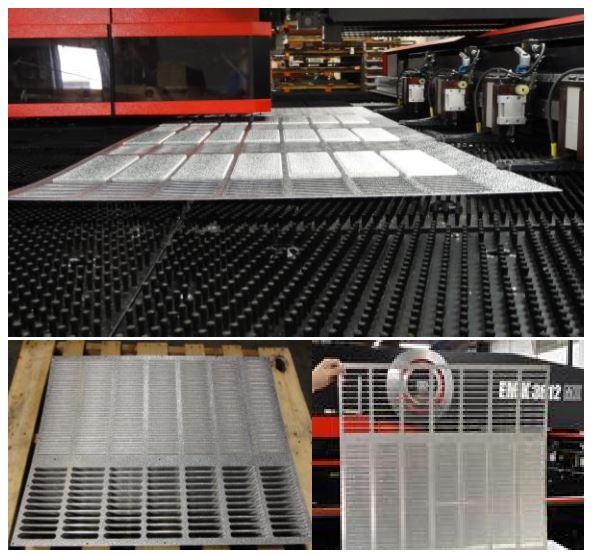

The EMK M2 is capable of producing complex parts with exceptional accuracy. It can create louvers, cutouts, tapped holes, and other special features to give you complete-to-print parts that match your exact specifications.

Tempco Amada EMK M2 Series Turret Press

Automated Material Tower

Contact Tempco for Our Turret Press Manufacturing Capabilities

To put our turret press and other high precision manufacturing capabilities to work for you, request a quote on the metal parts you need or contact Tempco to discuss your project.

©2024 Tempco Manufacturing Company, Inc.

2475 Hwy. 55, St. Paul, Minnesota 55120

Tel: 651-452-1441 Fax: 651-452-1125

Privacy Policy - Site Map - Site Credits: Ecreativeworks