Metal Stamping Quality Control Capabilities

At Tempco Manufacturing, we strive to provide the best-in-class technology to the highest quality standards. Our quality control equipment and precision testing standards are among the most stringent in the metal stamping industry. We uphold only the most rigorous quality control standards regarding precision operations, from material sourcing and selection to metal precision stamping.

Every step of our production processes and precision operations, including sheet metal fabrication, are inspected, passed, and approved to ensure the most efficient and quality level of manufacturing and service. Our manufacturing is backed by our quality certifications.

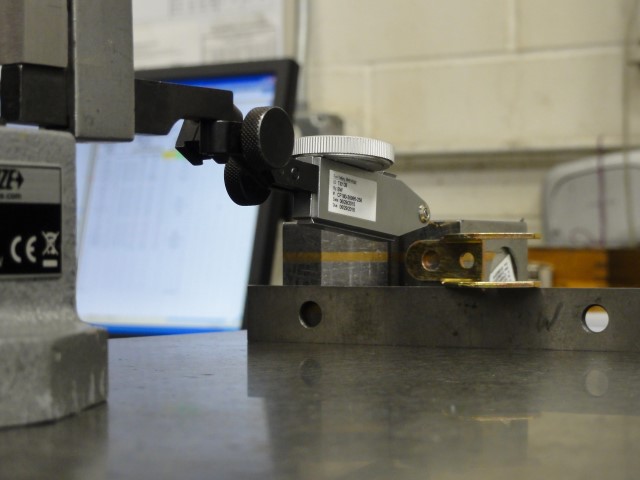

Quality Control Equipment

At Tempco, precision quality is always the foremost priority in any metal stamping or fabricating job we accept. We produce only the highest quality precision metal-formed parts. Our employees are dedicated and committed to quality through Quality Circle Involvement. The latest, up-to-date inspection equipment assures your parts are made precisely to the specifications you require. The following is a list of the quality control equipment we use to ensure product reliability and success.

Digital Measurement

-

Zeiss CMM Numerex 4040-24 C100 DCC

- Virtek Laser QC

- Keyence Image Measurement System

- Insight CMM 8106

Rockwell Testers

- Acco Wilson 3TT Hardness Tester

- Phasell Digital Hardness Tester

Tensile Strength Testers

- Lamina Checker

- 2 - Mitutoyo

SPC Measuring & Testing Equipment

-

Mitutoyo Digital Micrometer, 0-1”

- Mitutoyo Digital Caliper, 0-6”

- 10 Digital Height Gauges-12”

- 6 Digital Calipers 8”, 12’’, 24’’

- 1 Digital Fowler Height Gauge 24"

- 1 Digital Inside Height Gauge 24"

- 2 Mitutoyo Digital Caliper 24"

- 64 Thread Plug Gauges

- 1 Profilometer SRT 62005

- 1 Coating Thickness Gauge,Rositector 6000

- Tesa Hite, Digital Height Gauge 1075mm/27"

- PIN GAGE SETS

- VERNIER CALIPERS

- MICROMETERS

- SURFACE PLATES

Each piece of quality control equipment is designed to measure the effectiveness and accuracy of our services with the utmost precision. Click here to read more about our quality manufacturing processes.

Quality Control Metal Stamping Standards & Certifications

Tempco’s quality control metal stamping processes, including advanced quality certifications, registrations, and licensures, deliver knowledge and peace of mind that we provide you with the highest quality service in the industry. Our precision quality control metal stamping certifications include:

- AS9100D 2016 Certification

- ISO 9001:2015 Certification

- ISO 13485:2016 Certification

- Federal Firearms License

Contact Tempco for Metal Stamping Quality Control Standards & Equipment Today

At Tempco, we provide precision quality control testing standards via state-of-the-art quality control equipment. Request a quote today, or contact us to learn more about what makes Tempco Manufacturing the industry’s leading metal stamping and sheet metal fabrication company.

©2024 Tempco Manufacturing Company, Inc.

2475 Hwy. 55, St. Paul, Minnesota 55120

Tel: 651-452-1441 Fax: 651-452-1125

Privacy Policy - Site Map - Site Credits: Ecreativeworks